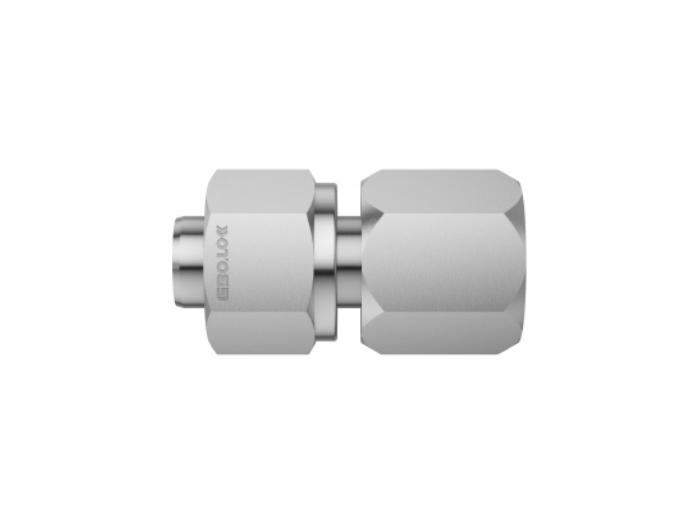

- Specification Parameters

- PDF Download

- Installation Instructions

Installation Instructions - End Joint

Please connect the end of the machined tubing before connecting the end of the tubing adapter.

End of machined card sleeve

Initial installation:

1. Remove the nut and sleeve from one of the two GBO-LOK connectors and discard the sleeve;

2. Tighten the sliding nut to the mechanical sleeve end connected to the hole;

3. Insert the port connector into GBO-LOK terminal 1 and tighten the nut by hand;

4. Secure the joint body firmly and use a wrench to tighten the nut by 1/4 turn. For 1/16 ", 1/8", 3/16 ", 2mm, 3mm, and 4mm tube fittings, use a wrench to tighten the nut by 1/8 turn.

Reinstall:

1. This type of terminal connection can be disassembled and reassembled multiple times;

2. When reassembling, tighten the nut by hand and then slightly tighten it with a wrench.

Tube adapter end

Initial installation:

1. Loosen the nut by 1/4 turn from the hand tight position;

2. Insert the tube into the sleeve connector, ensuring that the tube is pressed against the shoulder of the port;

3. Tighten the nut by hand;

4. Secure the body of the joint or valve firmly, use a wrench to tighten the nut 1-1/4 turn, and for small-sized joints (1/16 ", 1/8", 3/16 ", 2mm, 3mm, and 4mm), use a wrench to tighten the nut 3/4 turn.

Reinstall:

1. Before disassembling the joint, mark the pipe along the back of the nut; Draw a line on the plane of the nut and joint body;

2. Insert the card sleeve and tube assembly into the body until the front card sleeve is pressed against the joint body;

3. Securely fix the joint body and use a wrench to rotate the nut to the previously tightened position indicated by the markings on the pipe, nut, and body plane;

4. Gently tighten the nut again.

CHINESE

CHINESE

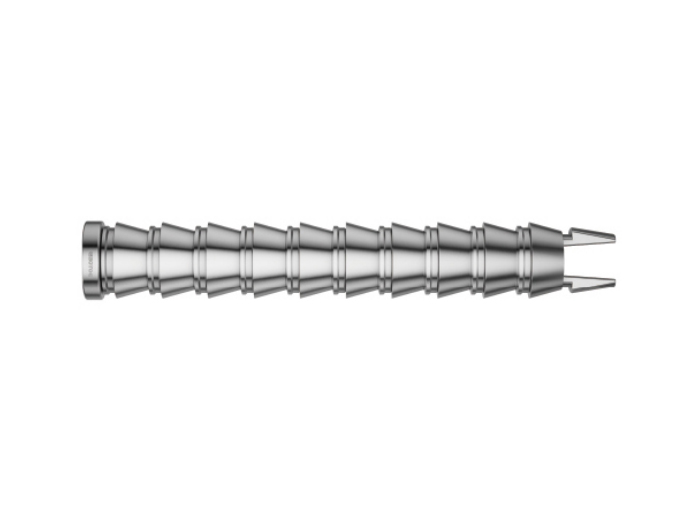

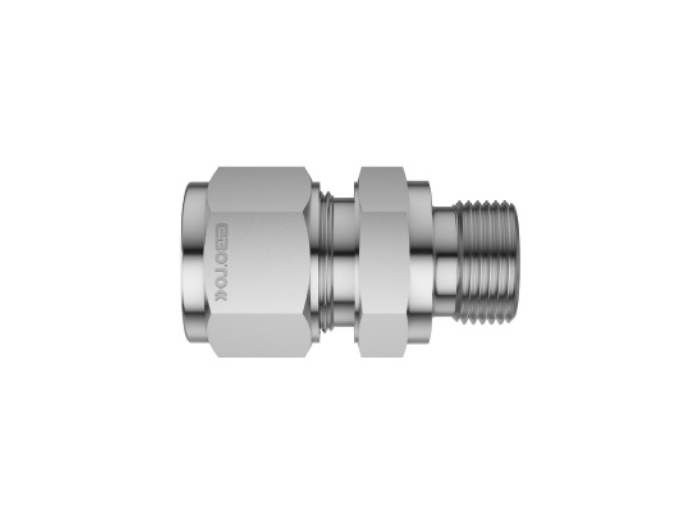

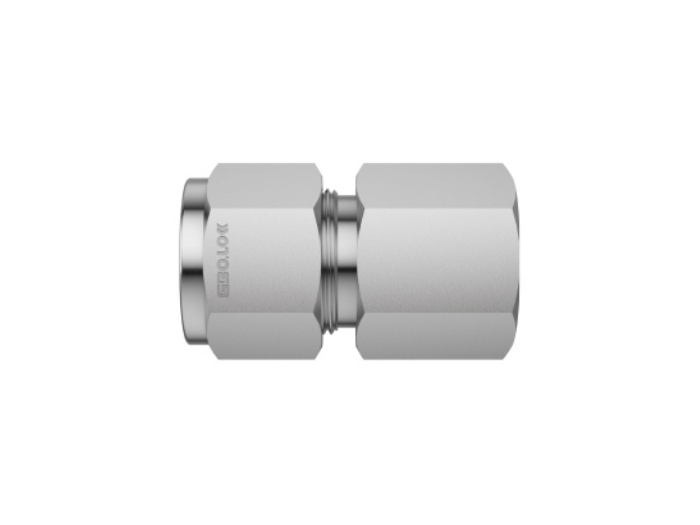

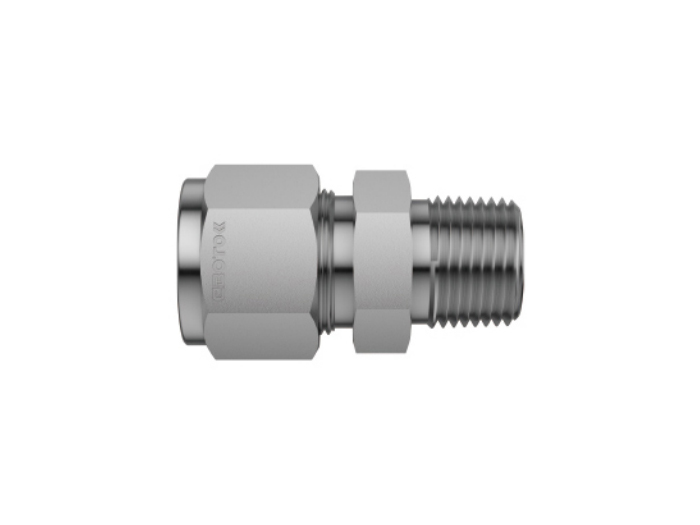

Double card sleeve joint

Double card sleeve joint

Contact Us

Contact Us