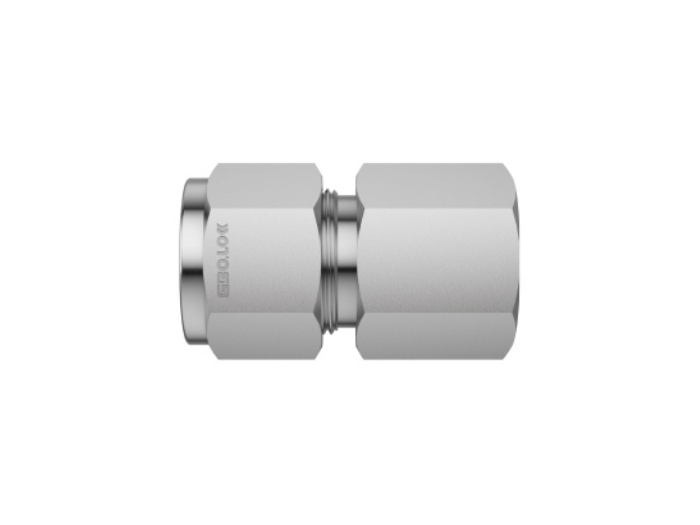

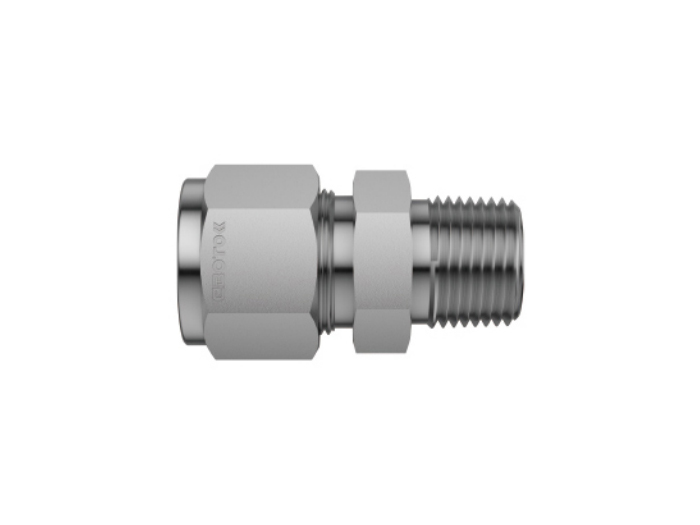

Installation instructions for card sleeve joint

1 "or 25mm and below card sleeve joint

Initial installation

1. Loosen the nut by 1/4 turn from the hand tight position;

2. Insert the tube into the sleeve connector, ensuring that the tube is pressed against the shoulder of the port;

3. Tighten the nut by hand;

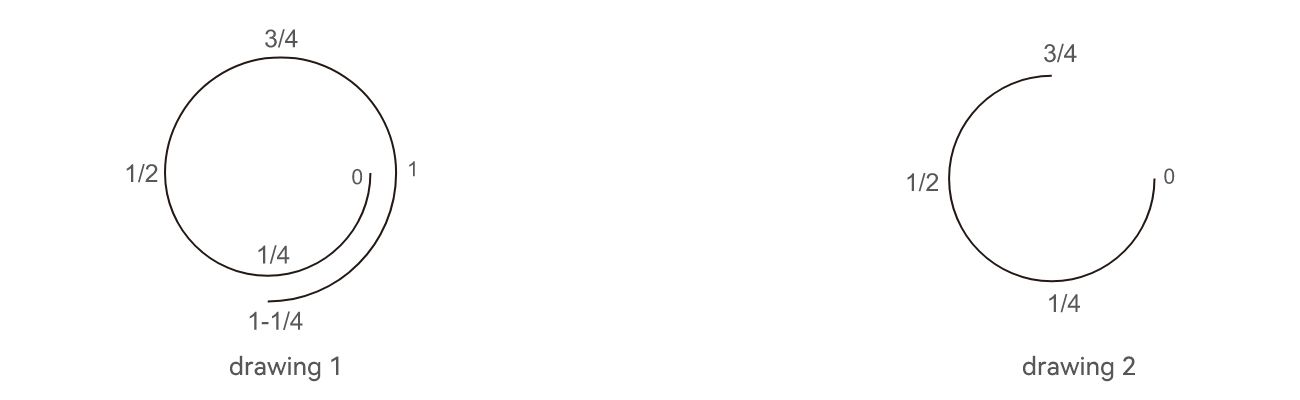

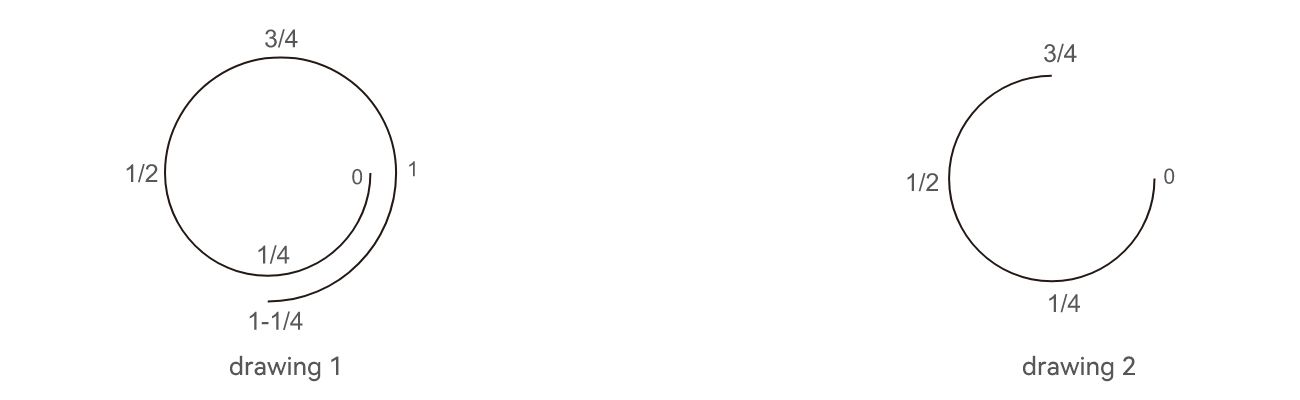

4. Secure the body of the joint or valve firmly, use a wrench to tighten the nut 1-1/4 turn (Figure 1). For small-sized joints (1/16 ", 1/8", and 3/16 ", 2mm, 3mm, and 4mm), use a wrench to tighten the nut 3/4 turn (Figure 2)

Reinstall

1. Before disassembling the joint, mark the pipe along the back of the nut; Draw a line on the plane of the nut and joint body;

2. Insert the card sleeve and tube assembly into the body until the front card sleeve is pressed against the joint body;

3. Securely fix the joint body and use a wrench to rotate the nut to the previously tightened position indicated by the markings on the pipe, nut, and body plane;

4. Gently tighten the nut.

Card sleeve joint larger than 1 "or 25mm

Initial installation

1. Install the card sleeve onto the Tube tube using a pre installation tool. For specific details, please refer to the instructions of each manufacturer's pre installation tool;

2. Insert the Tube tube with a sleeve and nut into the body of the joint, and tighten the nut by hand;

3. Tighten the nut 1/2 turn with a wrench.

Reinstall

The reassembly method is the same as that of card sleeve connectors with a diameter of 1 or 25mm or less.

Blocking head

Initial installation

Firmly fix the body of the joint and tighten the plug 14 times starting from the hand tight position. For small-sized joints (1/16 ", 1/8", and 3/16 ", 2mm, 3mm, and 4mm), use a wrench to tighten the nut 1/8 turn.

Reinstall

Starting from the tight position, use a wrench to slightly tighten.

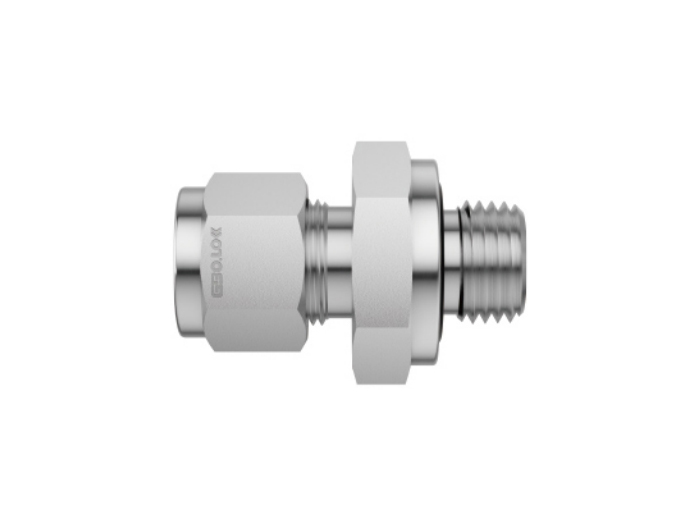

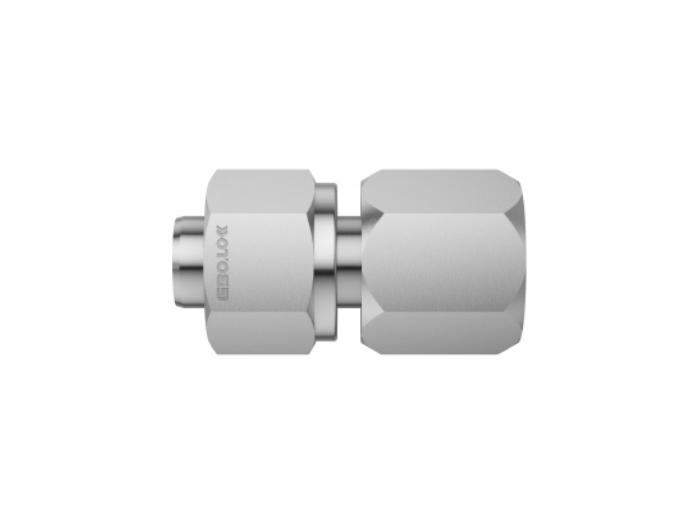

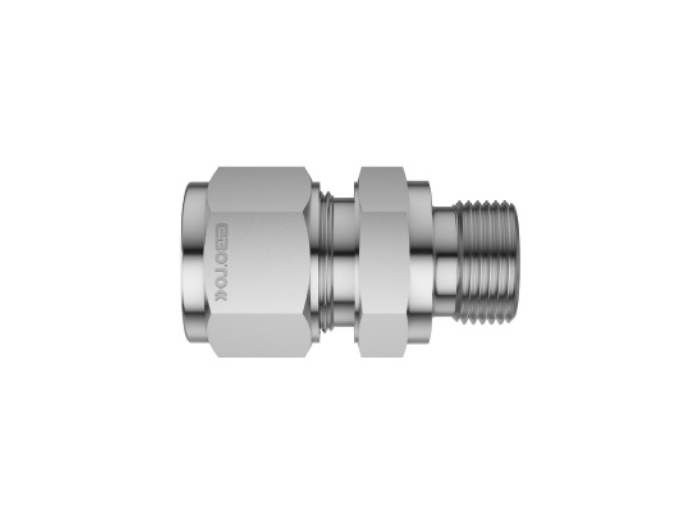

Port joint

The initial installation and reinstallation of the tube end are the same as those of the sleeve joint, while the initial installation and reinstallation of non tube ends are the same as those of the plug.

Warning:

1. Do not loosen or tighten the joints when the system is under pressure;

2. Ensure that the Tube tube is placed on the shoulder of the port during installation;

3. The tube end used for card sleeve joints should have a sufficiently long straight end;

4. For very soft plastic Tube tubes, a hose plug should be used;

5. The material of the tube should always be softer than the clamp joint. For example, brass sleeve fittings cannot be used for stainless steel Tube pipes. When the material of the tube and the sleeve joint are the same, the tube must undergo complete annealing;

6. Ensure that the end face and surface of the Tube tube are clean, smooth, and even;

7. Always use appropriate thread sealant on the taper pipe thread to ensure that the working temperature does not exceed the temperature at which the sealant is used;

8. When installing the card sleeve connector, use a wrench to fix the rotating nut of the body instead of fixing the nut to rotate the body;

9. When the sleeve end is used on the valve, the valve body should be fixed and the nut should be rotated;

10. When the sleeve joint is threaded with the valve, the valve body should be fixed and the sleeve joint body should be rotated.

CHINESE

CHINESE

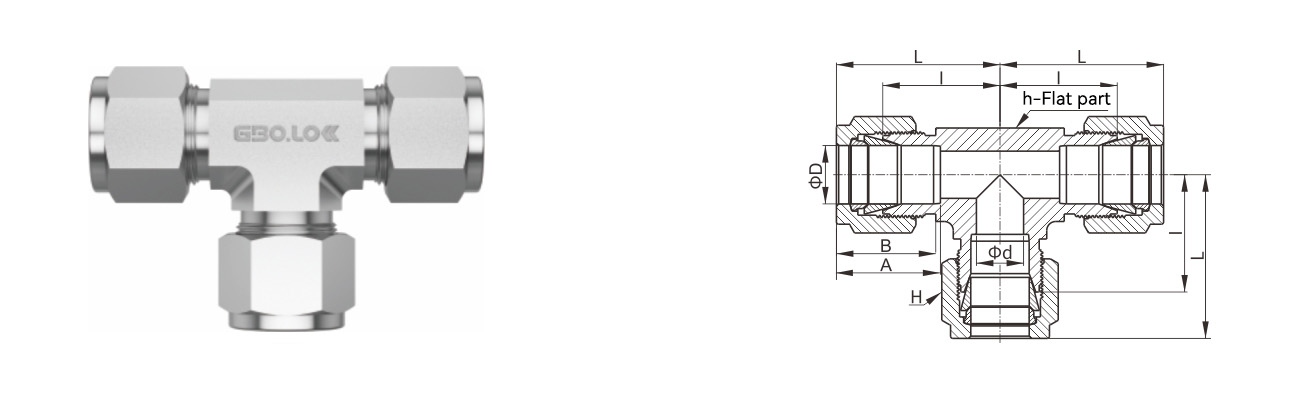

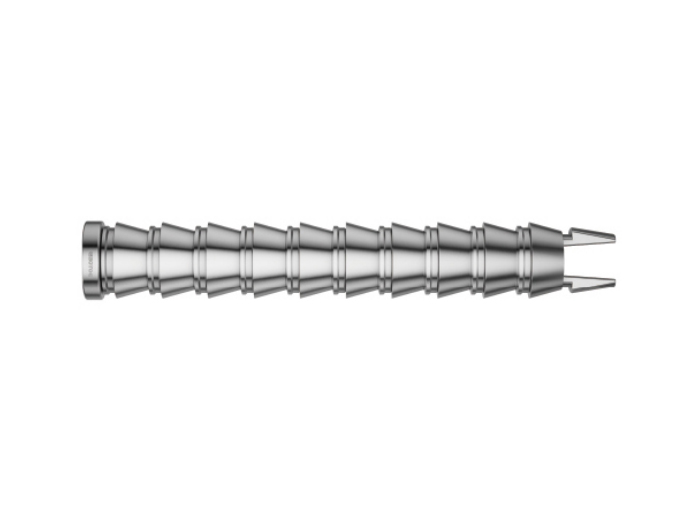

Double card sleeve joint

Double card sleeve joint

Contact Us

Contact Us